| Show general overview | Load overview |

| Special dimensions on request | Request now |

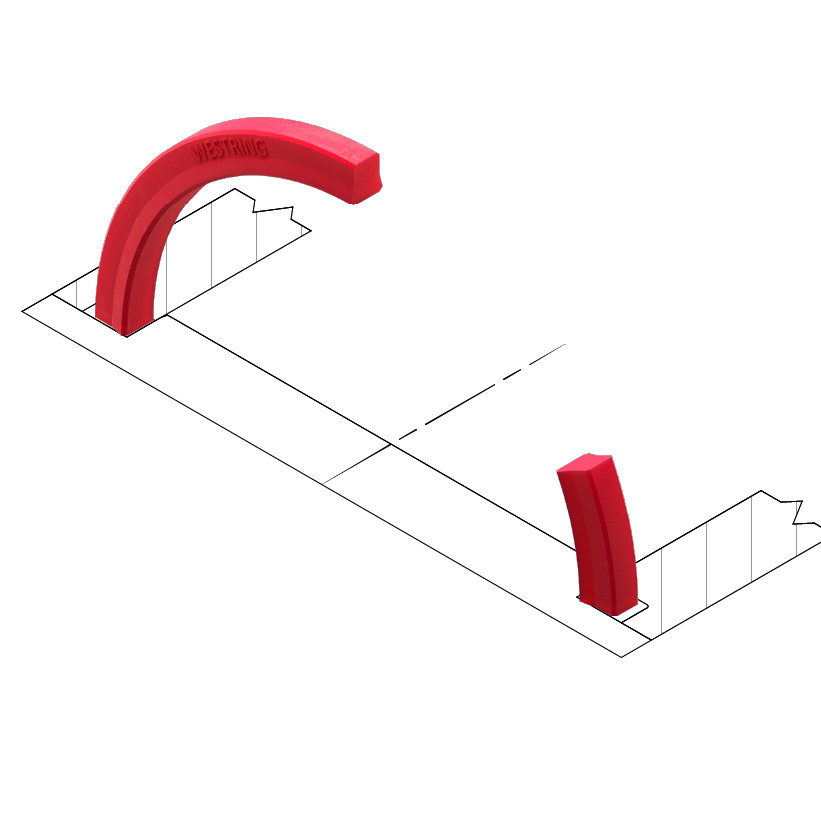

OVF

The flange seal profile OVF is a static seal. It is especially designed for SAE flanges. The good compression set value of the compound PU008 guarantees a high shape stability even after long working time. During pressure variations and surges with high pressure peaks this seal is superior to conventional O-ring seals. For the latter, it is possible that leakages occur due to pressure build-up in the groove area at the outer diameter. Additional, O-rings are often torn out of their position due to the pouring medium get lost or wear out because of the radial movement abilities. This can be avoided due to the special profile design of the flange seal OVF. There will be no free groove area at the outer diameter and the tight fit in the clearance is guaranteed.

ADVANTAGES ARE

- tight fit in the clearance

- insensitive to pressure surges ans pulsating pressures

- simple groove design

- no high demands to the surface quality

- high compressive capacity

| APPLICATION RANGE | |

| working pressure: | ≤ 60 MPa (600 bar) |

| working temperature: | – 35 bis + 110 °C |

MATERIAL

Standard compund is the PU-based PU008 with a hardness of approx. 93° Shore A and a very good compression set as well as hydrolysis.

MOUNTING INSTRUCTIONS

The seal may not stick out in to the oil-bearing through-hole. The clearance should be vented at the back of the groove, In general, the groove can be produced by use of a piloted counterbore.

For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy Service.

Download | Detailed product information (PDF 216.9 kB)