| Show general overview | Load overview |

| Special dimensions on request | Request now |

2.01

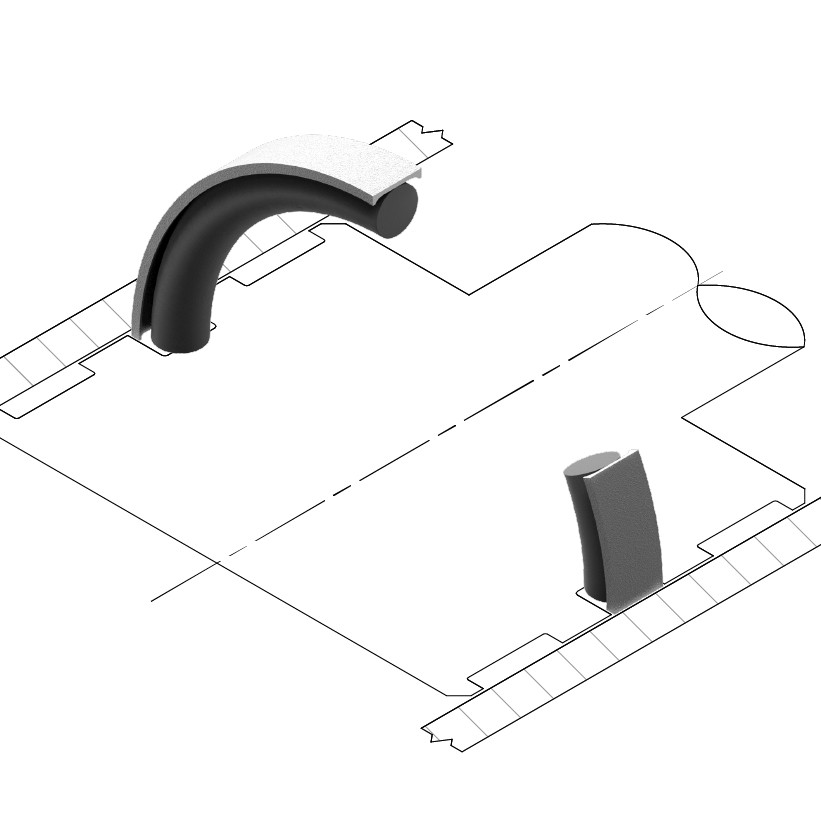

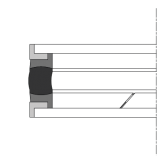

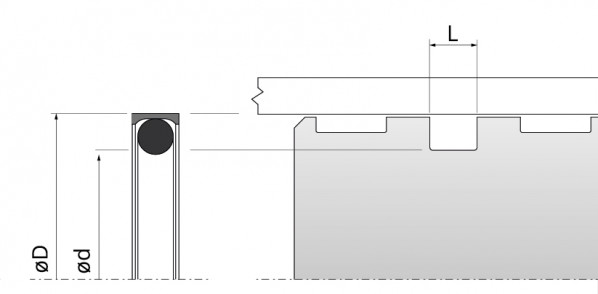

Kotef (piston seal) and Sotef (rod seal) are mutually acting seal elements consisting of a elastomer circular seal ring for the static pressure contact and a PTFE ring for the dynamic sealing.

The O-ring guarantees the pre-stressing for the seal and the necessary elasticity. Because of its static application, all circular seal ring materials can be used. As a consequence a high chemical and temperature resistance can be reached according to the choosing of the material. The known and good qualities of the PTFE material are effective in the dynamic acting slide ring. The static and the dynamic coefficient of friction are almost the same. Thereby a regular, undisturbed movement (no stick-slip) is guaranteed, even at slow surface speeds. After a longer standstill a calm starting is also secured. The sealing ring does not unroll. A pump effect, that can induce to smallest leakages at O-rings, is consequently eliminated. Due to the thin wall thickness of the PTFE, the sealing security is already assured at low pressures.

In special cases, the diameter of the groove can be slightly changed to further reduce the friction or to increase the pre-stressing. Please contact our consultancy service for this purpose.

ADVANTAGES ARE

- small fitting area

- high availability also in intermediate sizes

- universal chemical resistance

- high resistance to temperature

- good dry operation attributes

- high security from extrusion

- small breakaway torques and sliding friction

- no stick-slip even at low speed

- small abrasion

| APPLICATION RANGE | |

| Working pressure: | ≤ 20 MPa (200 bar) |

| Working temperature: | - 40 °C to + 100 °C |

| - 25 °C to + 200 °C (depending on the O-ring) | |

| Surface speed: | ≤ 3 m/s continuous |

| ≤ 10 m/s intermittent | |

| Media: | all hydraulic fluids, e.g. water, oils, water-oilemulsions, flame-proof |

| hydro-oils etc. (depending on the O-ring compound) | |

In general for short strokes in pneumatic and hydraulic cylinders, pneumatic and hydraulic controllers, regulating, safety and sanitary valves, fittings, etc.

| MATERIAL | |

| Slide ring: | PT044 |

| O-ring: | NBR-elastomer with approx. 70 Shore A |

INSTALLATION

To avoid the damaging of the seal sharp edges may not be overrun. Normally Kotef is mountable with assembly aid on closed grooves from a diameter of 40 mm. Sotef is mountable from a diameter of 50 mm on closed grooves.

For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

|  |

Download | Detailed product information (PDF 592.8 kB)