| Show general overview | Load overview |

| Special dimensions on request | Request now |

2.12

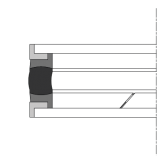

Keilpac (piston seal) and Skeilpac (rod seal) are single acting seal elements consisting of a elastic circular seal ring and a wedge-shaped PTFE ring. On the one hand the circular seal ring serves as a static sealing and on the other hand as a pressure-dependent spring for the plastic, dynamic sealing PTFE ring. Therefore all elastomeres can be used. The seal is depending on pressure. This opens a large field of application for the seal in tandem with the material PTFE. Particularly with regard to the chemical and temperature resistance and all of that without long terms of delivery or high expenses.

Other known attributes of the material PTFE are effective within the dynamic part of the seal. From this follows low friction, high abrasion resistance, good dry operation attributes, no swelling and dirt resistance. The static and the dynamic coefficient of friction are almost the same. Thereby a regular, undisturbed movement (no stick-slip) is guaranteed, even at slow surface speeds. After a longer standstill a calm starting is also secured. Keilpac and Skeilpac are qualified for both axial and rotating movements. According to the PTFE mixture corresponding PV-limits are setted. That implies the necessity to state the max. pressure in bar, the max. speed in m/s and the max. operating temperature with the order.

ADVANTAGES ARE

- small fitting area

- high availability also in intermediate sizes

- universal chemical resistance

- reliably sealing also at highest pressures

- good dry operation attributes

- small breakaway torques and sliding friction

- no stick-slip even at low speed

- use even on dirty conditions like plunger pumps for mud of cement

| APPLICATION RANGE | |

| working pressure: | ≤ 30MPa (300 bar)without back-up ring - standard |

| ≤ 50 MPA (500 bar) with back-up ring | |

| to be orderd extra | |

| working temperature: | - 35 °C to + 100 °C |

| - 25 °C to + 200 °C (depending on the O-ring) | |

| surface speed: | ≤ 3 m/s continuous |

| ≤ 10 m/s intermittent | |

| media: | all hydraulic fluids, e.g. water, oils, water-oilemulsions, |

| flame-proof hydro-oils etc. (depending on the O-ring compound) |

Most commonly used at the hydraulics and also pneumatics, such as working cylinders, piston pumps, valves, hydraulic pressings, machine tools, construction machines, etc.

| MATERIAL | |

| Slide ring: | PT044 |

| O-ring: | NBR |

INSTALLATION

To avoid the damaging of the seal sharp edges may be overrun. Normally Keilpac and Skeilpac are mountable on closed grooves from a diameter of 50 mm. Divided fitting rooms are recommendable. For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

|  |

Download | Detailed product information (PDF 615.3 kB)