| Show general overview | Load overview |

| Special dimensions on request | Request now |

GDS

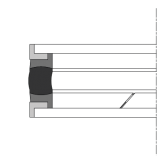

The lip seal GDS is a totally symmetric lip seal which consist of hydrolysis restistent polyurethane with an oversize at the external diameter. By this a tight fit in the groove is ensured. By means of its symmetric profile construction, this seal may be insert likewise as a rod seal and a cylinder seal.

ADVANTAGES ARE

- very high wear resistance

- insensitive to high and pulsating pressure peaks

- resistant against gap extrusion

- low compression set

- qualified for hardest working conditions

| APPLICATION RANGE | |

| working pressure: | ≤ 35 Mpa (350 bar) |

| operating temperature: | – 35 up to + 110 °C |

| surface speed: | ≤ 0,5 m/s |

| medium: | Hydraulic oils (mineral oil based) |

Mainly used for the spare parts demand, more exactly for the sealing of piston rods and plungers in heavy duty applications in mobile and stationary hydraulics. For new constructions the profiles B3R and B7P are recommended.

MATERIAL

PU013 is a resistant-to-wear polyurethane material with a Shore hardness of approx. 93 A. Its main advantages compared to other polyurethane materials usual in the trade are: High heat stability, good behave against hydrolysis and low compression set values.

MOUNTING INSTRUCTIONS

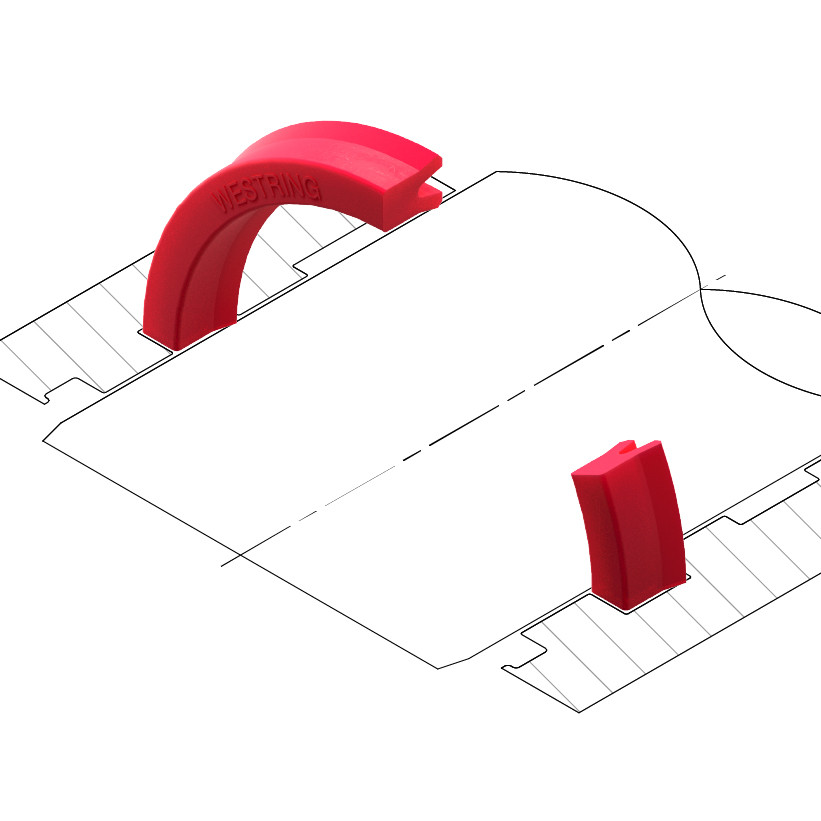

To ensure a faultless function, the GDS should have an axial clearance (see measure table). To avoid damages at the sealing lip, the seal should not to be pulled over sharp edges. In normal cases the GDS may be installed into closed grooves.

Where extremely width of the profile or relations of the diameter are existing assembly tools may be required or use of a splitted groove. Normally the fit should be H8/f7. A larger gap size at the back of the seal is possible when lower pressures are obtaining.

For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

Download | Detailed product information (PDF 444.0 kB)