| Show general overview | Load overview |

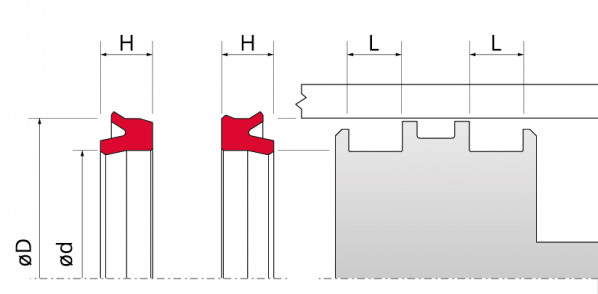

| Special dimensions on request | Request now |

General

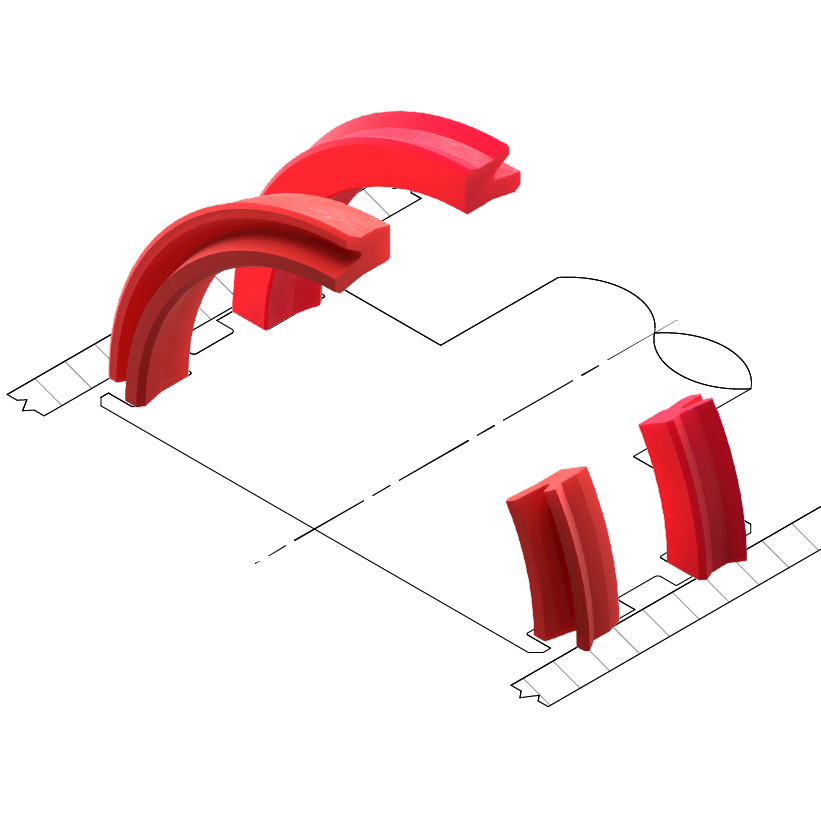

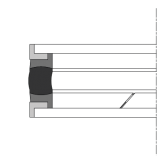

The KSP profile is a two-part seal set for separating pistons, especially for piston accumulators, consisting of a TPU lip seal of approx. 90 Shore A for the gas side and a TPU lip seal of approx. 94 Shore A for the oil side. The special design of the seals ensures low-friction and reliable separation of the different pressure media. They have been optimised to achieve a high energy recovery with the lowest possible energy loss for stationary and mobile industrial hydraulics. Both lip rings have a special lip and back geometry for their respective application side and have a significantly higher degree of tightness with almost the same coefficients of friction compared to PTFE sliding rings.

Medium

Fluids and gases for use in piston accumulators

Material

Standard materials: PU013 94 Shore A, PU010 90 Shore A

Advantages

- high degree of tightness with low friction

- low energy loss or high energy recovery

- high design flexibility due to free arrangement

Installation instructions

In principle, the seal kit can be mounted on one-piece pistons. In this case, the pressure-facing piston cheek of the groove should recede in diameter by 1/3 of the radial height of the seal profile. For series assembly and small diameters, a monogate tool is advantageous. To avoid damage, the seals must not be pulled over sharp edges and corners. The general instructions also apply. For special applications (pressure, temperature, sliding speed etc.) please contact our application engineering department.

Area of application

Industrial shock absorbers, hydro-pneumatic elements, pressure intensifiers, pressure medium converters, feed and brake units