| Show general overview | Load overview |

| Special dimensions on request | Request now |

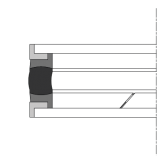

General

The piston seal T2P, colloquially known as a cup seal, is a simple seal for simple applications in the low pressure range. Pressure is applied to the face of the sealing lip. For alternating pressure application, two cup seals mounted in opposite directions and installed in their own grooves can be used. Can also be used in pneumatics for special mixtures. Also available in MF version (with spring).

Medium

Mineral oil, bio-oil, pressure fluids HFA, HFB, HFC (VDMA 24317)

Material

Standard material: NBR with a hardness of 80-90 Shore A. FKM and EPDM are also available for special applications. For high application pressure, a wear-resistant HPU may be recommended.

Advantages

- easy assembly from the outside

- wide range of materials

- quick disassembly and assembly for replacement

Installation instructions

Correct functioning of the cup seal requires careful installation. The axial compression on the flange of the gasket should be about 10% of the flange thickness. The design should be such that the compression is metallically defined in order to avoid further force transmission and deformation of the sealing lip. In order to achieve an improvement of the fixing and sealing effect of the cup collar, it is recommended to turn one or two sealing grooves into the metallic flange surfaces. In special applications (high temperature, speed, specific pressure load or use in brake fluid, HFA, HFB fluids etc.) please contact our application engineering department.

Other

For operating pressures greater than 1MPa (10 bar), a metallic support ring is required, which also serves as a guide element when paired with the cylinder barrel in the appropriate material selection.

Range of application

Low pressure hydraulics, pneumatics