Diese Maße bearbeiten wir auf Ihre individuelle Anfrage hin. Please contact us for your customised requirement.

General

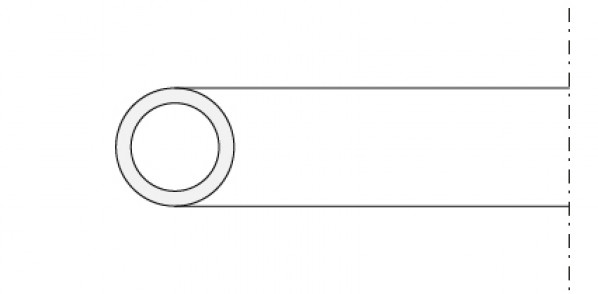

Metal O-rings have been developed for use in extreme operating conditions as a secure seal for gases or liquids. These static, metallic sealing elements can be used in areas of ultra-high vacuum and up to a pressure of 5000 bar. They can be used at Continuous temperatures from -269°C to +750°C and are resistant to radioactive radiation, chlorides, corrosion and other aggressive influences. They do not age in use or during storage.

Medium

Can be used against almost any liquid or gaseous medium

Material

Various alloys and coatings or galvanisation possible.

Advantages

With conventional flange connections, a lot of technical data must be available for the calculation, of which very little is known exactly in the design phase. Likewise, the values for the stiffness of the flange, the bolts, etc. must be available. Extensive calculations with inaccurate or assumed values and the associated disadvantages are the result. With the metal O-rings or U-Cups you always have a defined preload, no settling and smaller flange and bolt dimensions. You don't have to prove it with cumbersome, difficult calculations over many unknown quantities, but simply add the pressing forces to the operating forces.

Installation instructions

The correct dimensions and surface quality of the groove are just as important for the sealing application as the O-ring itself. Further information can be found in the enclosed data sheet.

Other

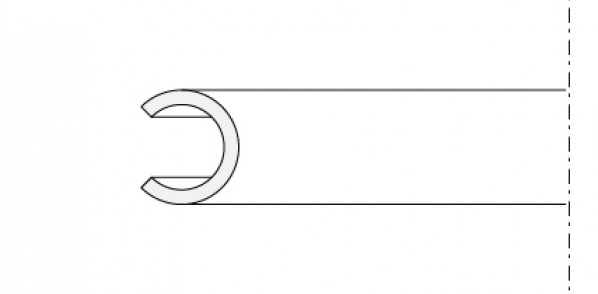

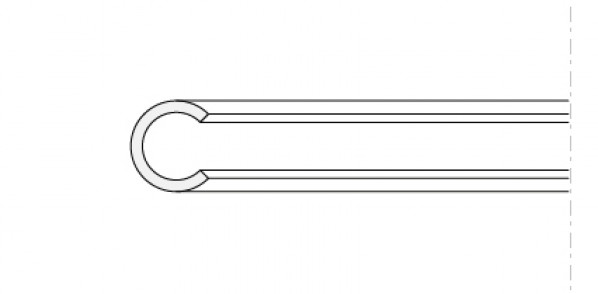

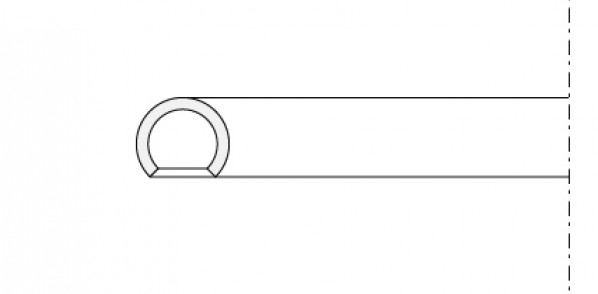

Various application-dependent profile shapes available. Normal design, pressure-filled design, self-reinforcing design, C-ring or M-ring.

Range of application

As a typical application, the metal O-ring is pressed axially between parallel surfaces arranged at right angles to the flow or the vessel. The seal is usually placed in an open or a closed groove. It can also be placed in a retainer. This can eliminate the need to machine a groove. When compressed to a predetermined, fixed height, the tube material of the seal buckles slightly. This creates two contact areas on the Contact areas on the gasket surface and a maximum contact stress between the gasket and the mating surface. By closing two flanges and the resulting compression of the O-ring, a spring-back effect is achieved which exerts a positive force. In the self-reinforcing design of metal O-rings, the system pressure increases the sealing force on the flange surface.

Download | Detailed product information (PDF 2.1 MB)