| Show general overview | Load overview |

| Special dimensions on request | Request now |

General

Round cords are generally used as a substitute for very large O-rings in simple applications, if no moulds for endless O-rings according to DIN 3771 can be used here or the small number of pieces does not justify the production of a mould for cost reasons. While the O-ring is a pure moulded part, i.e. it is pressed in a vulcanising mould, the toroidal sealing ring is created by connecting a toroidal cord to a ring by bonding or vulcanisation. Since the round cord is manufactured in a strangextruded version, unlike shape-vulcanised O-rings, it has greater dimensional tolerances with regard to the cord thickness. Compared to O-rings, the material properties are also inferior. Unsuitable for vacuum applications.

Medium

various media such as mineral oils, water etc.

Material

Standard materials: Elastomers in NBR, EPDM, CR, FKM, MVQ from 60-75 Shore A. Other material hardnesses and HPU mixtures are possible for special applications.

Advantages

- inexpensive option as a replacement for large, endless O-rings

- short procurement time for normal shore hardnesses

- can be welded well as an O-ring in PUR

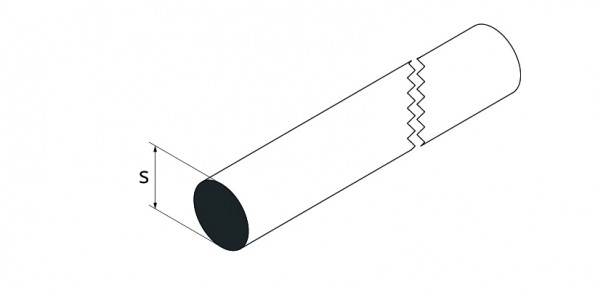

Installation instructions

Please note the larger tolerance range for the cord diameter. The design of the installation spaces is based on the specifications for O-rings. For circumferential, non-circular grooves, a bending radius r > 1.5 x cord thickness is recommended. It is also important to select the right material for the respective application. You can find the media resistance in our media resistance list. For special applications, please contact our application engineering department.

Other

A suitable cyanoacrylate adhesive or, even better, a 2-component adhesive should be used to bond the round cord. The gluing area must be slightly roughened and free of grease before gluing. The maximum temperature resistance of the adhesive depends on the adhesive used.

Area of application

plant and mechanical engineering, chemical industry, automotive industry, etc