| Show general overview | Load overview |

| Special dimensions on request | Request now |

The O-ring profile V1S is made of a hydrolysis resistant polyurethane compound. It is more resistant to extrusion than standard O-rings (NBR, FPM, EPDM, etc.). Therefore, he is especially suitable for applications with small clearance not allowing the use of a back-up ring. It is also suitable for high and pulsating pressure. Additional, they can overrun bores at valce control spools, whereas this O-ring has an obviously longer service life than other rubber compounds. With a novel method the O-rings V1S can be produced short-dated and cheap in any dimensions. Above all this is an asset at large flange seals, where the rubber compounds needed are not available.

ADVANTAGES ARE

- high resistance to extrusion

- little space requirement

- higher dimension accuracy than conventional O-rings according to DIN 3601

- higher resistance to abrasion

- producible short-dated and cheap in any dimensions

APPLICATION RANGE

| working pressure: | ≤ 600 bar |

| working temperature: | -35 °C to +100 °C |

| for use in water, HFA and HFB-fluids: | max. +50 °C |

| surface speed: | ≤ 0,5 m/s |

| media: | Hydraulic oils (mineral oil based), HFA and HFB fluids |

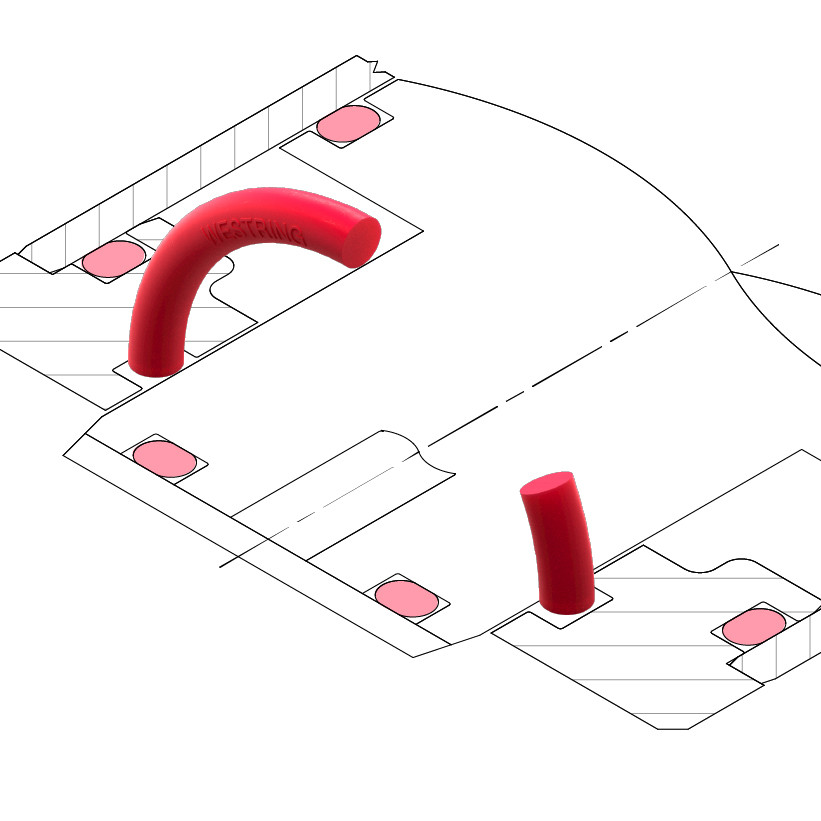

APPLICATION FIELD

- high pressure hydraulics.

- high pressure flange seals.

- in pneumatic valves for pre- and main valve control spool seals

- as piston seal in short stroke support and stress cylinders

- in valves of plants where poor lubricating HFA fluid goes into action

MATERIAL

PU008 is a hard-wearing polyurethane compound a hardness of approx. 93 Shore A. Its main advantages in comparison with other polyurethane materials available on the market are: lower compression set, higher heat resistance, better performance against hydrolysis.

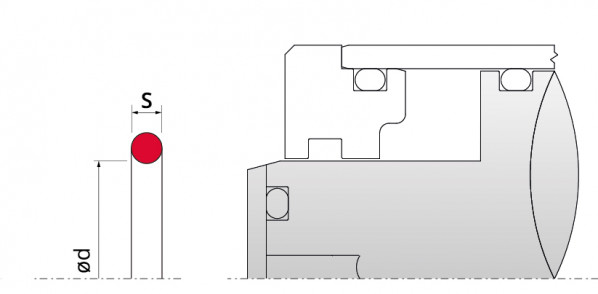

INSTALLATION

The housings are slightly different from those of standard O-rings. In the case of special applications, please discuss your problems with our consultancy service.

| s R (mm) | Groove depth (radial) t (mm)* | Groove width | |||||||

| static | dyn. Hydr. | dyn. pneu. | without Back-up | ||||||

| 1,00 | 0,2 | 0,65 | ± 0,05 | 0,75 | ± 0,02 | 0,80 | ± 0,02 | 1,4 | ± 0,02 |

| 1,50 | 0,2 | 1,05 | ± 0,05 | 1,20 | ± 0,02 | 1,25 | ± 0,02 | 2,0 | ± 0,02 |

| 1,80 | 0,2 | 1,30 | ± 0,05 | 1,45 | ± 0,02 | 1,55 | ± 0,02 | 2,4 | ± 0,02 |

| 2,00 | 0,2 | 1,50 | ± 0,05 | 1,65 | ± 0,02 | 1,75 | ± 0,02 | 2,7 | ± 0,02 |

| 2,50 | 0,2 | 1,95 | ± 0,05 | 2,10 | ± 0,02 | 2,20 | ± 0,02 | 3,4 | ± 0,02 |

| 2,65 | 0,3 | 2,05 | ± 0,05 | 2,25 | ± 0,02 | 2,35 | ± 0,02 | 3,6 | ± 0,02 |

| 3,00 | 0,3 | 2,40 | ± 0,05 | 2,55 | ± 0,02 | 2,70 | ± 0,02 | 4,2 | ± 0,02 |

| 3,50 | 0,3 | 2,80 | ± 0,07 | 3,05 | ± 0,05 | 3,20 | ± 0,05 | 4,8 | ± 0,02 |

| 3,55 | 0,3 | 2,85 | ± 0,07 | 3,10 | ± 0,05 | 3,25 | ± 0,05 | 4,8 | ± 0,02 |

| 4,00 | 0,3 | 3,25 | ± 0,07 | 3,50 | ± 0,05 | 3,65 | ± 0,05 | 5,4 | ± 0,02 |

| 5,00 | 0,3 | 4,15 | ± 0,10 | 4,45 | ± 0,05 | 4,65 | ± 0,05 | 6,8 | ± 0,02 |

| 5,30 | 0,5 | 4,40 | ± 0,10 | 4,70 | ± 0,05 | 4,90 | ± 0,05 | 7,2 | ± 0,02 |

| 7,00 | 0,5 | 5,85 | ± 0,10 | 6,25 | ± 0,05 | 6,55 | ± 0,05 | 9,6 | ± 0,02 |

For dynamic applications the following minimum cross-sections “s” apply because of the twisting risk:

s = 5,7 mm to diameter d ≤ 150 mm

s = 7,0 mm to diameter d ≤ 200 mm

For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.