| Show general overview | Load overview |

| Special dimensions on request | Request now |

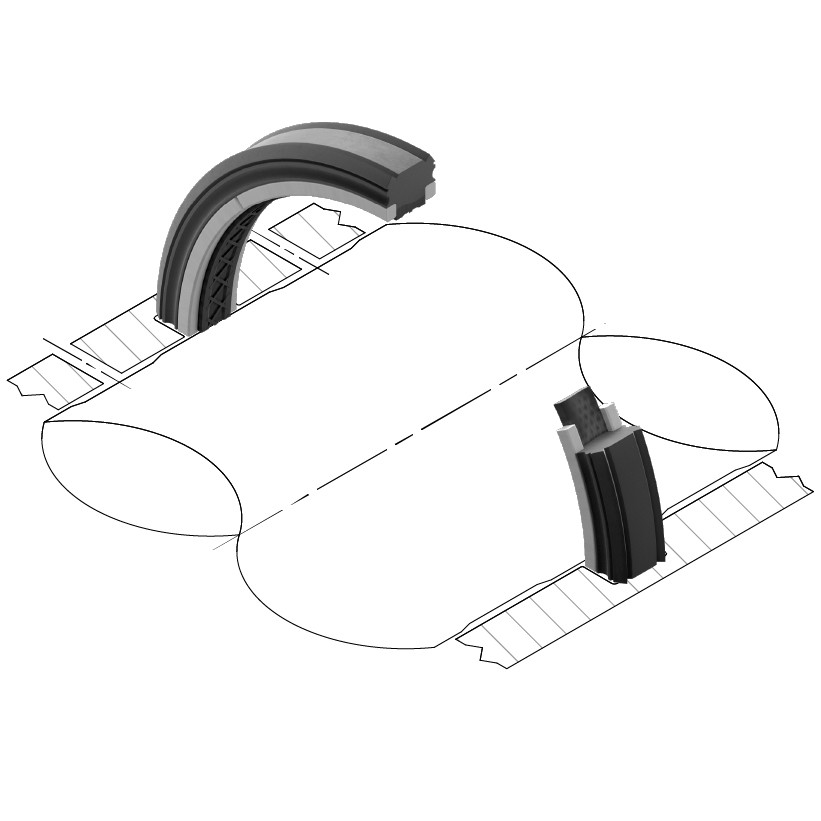

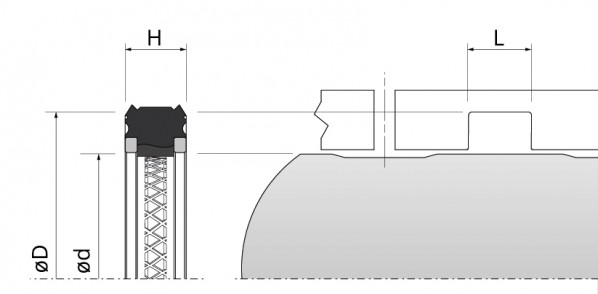

KAR

The profile KAR rotary sealing set consists of a rubber sealing part that has a profiled fabric crown on the inside. Laterally two back-up rings are located. These ones add to more stability in the seal and prevent an extrusion into the gap. Because of the rotation, the gap is mostly variable. Due to the special design of the dynamic surface at the inside dimension, a lubrication reservoir will be built up retaining the lubrication film and avoiding dry operation.

| APPLICATION RANGE | |

| working pressure: | 31,5 MPa |

| working temperature: | - 30 °C to + 100 °C |

| surface speed: | ≤ 0,2 m/s |

| recommendation: | PxV ≤ 0,5* |

Mainly for applications with cycling loadings for the seal, such as pivots for rotating track rings, swivel joints, hose reels, and in machine tool hydraulics.

MATERIAL

Standard compound for the sealing part is a NBR elastomer with fabricreinforced dynamic surface (Z5011/Z5014). The back-up rings are made of a polyamid-based material.

MOUNTING INSTRUCTIONS

The seals are designed to be snapped into closed grooves. Special versions for open grooves in endseal applications are available. During installation, first the sealing part must be installed, followed by the backup ring. To avoid damaging the seal, no sharp edges should be located within the installation area. For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

* Product from pressure (MPa) and slidding speed (m/s) should not exceed 0,5.

| Temperature °C | max. perm. pressure |

| 60 | 40 MPa (400 bar) |

| 80 | 31,5 MPa (315 bar) |

| 100 | 25 MPa (250 bar) |

Working pressure depending on the temperature.

Download | Detailed product information (PDF 397.0 kB)