| Show general overview | Load overview |

| Special dimensions on request | Request now |

ORR

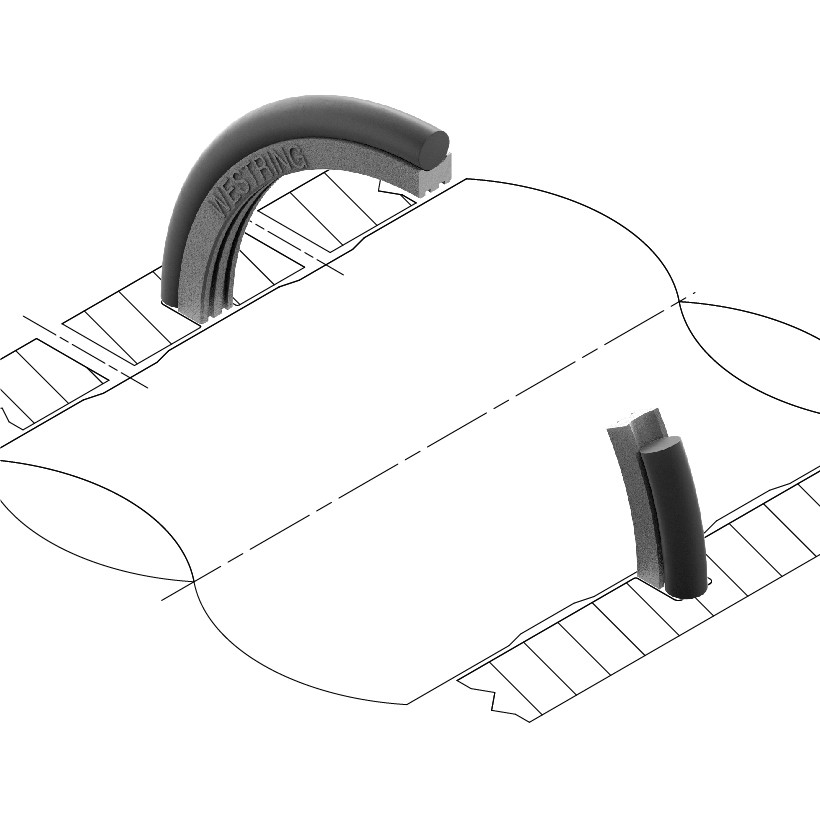

The inside sealing rotary seal set ORR is a double acting seal element, which can be impinged with pressure double-sided or reciprocal. It consists of a high-grade PTFE ring for the dynamic sealing (primary sealing) and an O-ring as an elastic pretension element (secondary sealing). The manufacturer of pivoting motors require simplified seal constructions – this seal set is up to these marks. The special tread design is especially well qualified for the use at high pressures and low slide speeds. According to the profile cross section, one or two circulating grooves are inwrought in the tread. Thereby a higher specific surface pressure against the surface to be sealed is reached and thus a better seal effect is achieved. Simultaneous the friction is reduced by the establishment of lubrication grooves. On the lateral surfaces notches are fixed for a better pressure activation. By using the seal set as a final sealing, the construction should be combined with a wiper ring.

ADVANTAGES ARE

- small, simple fitting area

- good availability even in intermediate sizes for diameters up to 2.500 mm

- universal chemical resistance

- high temperature resistance

- high security from extrusion

- small breakaway torques and sliding friction

- no stick-slip even at low speed

- small abrasion

- mounting in closed fitting areas (> 15 mm rod diameter)

| APPLICATION RANGE | |

| working pressure: | 30 MPa (300 bar)* |

| working temperature: | - 35° to + 100 °C (200 °C depending on the O-ring)** |

| surface Speed: | ≤ 1 m/s |

| media: | all hydraulic fluids, e.g. water, oils, water-oilemulsions, flame-proof hydro-oils, environmentfriendly pressure fluids (bio-oils) etc. - depending on the O-ring |

| Information: | P x v ≤ 4(Surface speed [m/s] and pressure [MPa]) |

We recommend to use guiding elements with this seal. Chiefly in rotary distributors, pivoting drives in the mobile hydraulics and in machine tools, hose barrels.

| MATERIAL | |

| Slide ring: | PT033 or PT074 |

| O-ring: | NBR elastomer with approx. 70 Shore A |

ORDER EXAMPLE

Rod diameter: 80 mm

ORR 0800 PT033 16N1 D

| ORR = | Profile |

| 0800 = | Rod Ø x 10 |

| PT033 = | Compound |

| 16N1 = | Serial number, Last digit: O-ring-code |

| D = | Cross section |

PLEASE NOTE

For special applications it is recommendable to use a sealing cross section, reduced or stepped up, that differs from standard, In these cases replace the standard cross section code (e.g. „D“) by the desired one (e.g. „C“ or „E“).

INSTALLATION

To avoid damage to the sealing lip, the seals should not be drawn over sharp edges during installation. In normal case the ORR is mountable on closed grooves froma diameter of 15mm. The fitting areas are to be deburred and to be cleaned thorough. The shafts must own lead-in chamfers. For special cases of application (high temperatures, speed, specific pressure, use inwater, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

* At reduced extrusion gap (H7/f7) up to 400 bar.

** At deviations from the standard temperature, please make an enquiry about the O-ring compound.

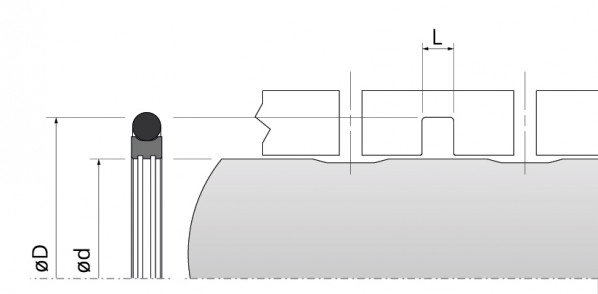

HOUSING DIMENSIONS

| Series no. | Cross-section | O-ring | Recommend Piston Ø range | Groove width | Groove depth | Gap max. | gap max. | Radius max. | |

| Cross-section | d (mm) | 0-200 bar | 200-400 bar | ||||||

| NBR 70 | (mm) | ≥ | < | L (mm) | G (mm) | e (mm) | e (mm) | R1 (mm) | |

| 16 N1 | A | 1,78 | 4 | 8 | 2,2 | 2,45 | 0,4-0,2 | 0,2-0,1 | 0,5 |

| 16 N1 | B | 2,62 | 8 | 19 | 3,2 | 3,75 | 0,4-0,2 | 0,2-0,1 | 0,5 |

| 16 N1 | C | 3,53 | 19 | 38 | 4,2 | 5,50 | 0,6-0,3 | 0,3-0,2 | 0,5 |

| 16 N1 | D | 5,33 | 38 | 200 | 6,3 | 7,75 | 0,8-0,4 | 0,4-0,2 | 0,9 |

| 16 N1 | E | 6,99 | 200 | 256 | 8,1 | 10,50 | 1,0-0,5 | 0,5-0,3 | 0,9 |

| 16 N1 | F | 6,99 | 256 | 650 | 8,1 | 12,25 | 1,0-0,5 | 0,5-0,3 | 0,9 |

| 16 N1 | G | 8,40 | 650 | 1000 | 9,5 | 14,00 | 1,0-0,5 | 0,5-0,3 | 0,9 |

O-RING DESIGNATIONS IN PTFE-SEALS

| Material | Shore | OR-Code |

| NBR | 70+/-5 | N1 |

| FKM | 75+/-5 | V2 |

| NB 304 (HNBR) | 75+/-5 | N3 |

| EPDM | 75+/-5 | E4 |

| NB 578 | 75+/-5 | N5 |

| NBR | 90+/-5 | N6 |

| Silikon | 70+/-5 | S7 |

| HNBR | 80+/-5 | N8 |

| FFKM | 80+/-5 | V9 |

Download | Detailed product information (PDF 461.1 kB)