| Show general overview | Load overview |

| Special dimensions on request | Request now |

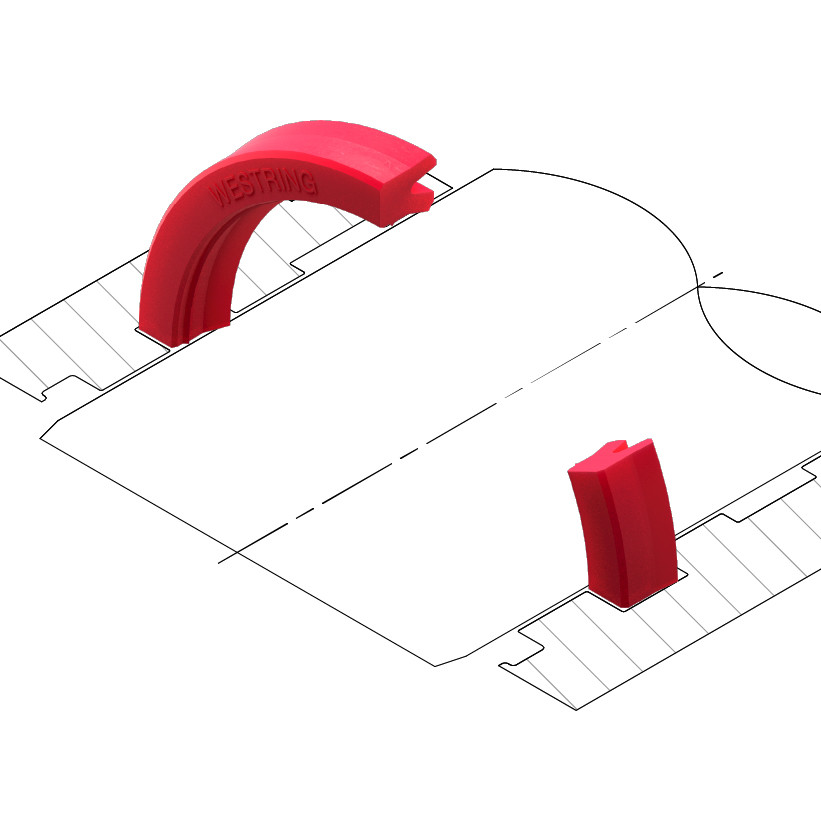

BSR

The HPU rod seal BSR profile is a lip seal with oversize, related to the external diameter, which also comes with a second sealing lip. Through this a tight hold will be created and between the two sealing lips a lubrication film generated, which prevents dry operation. Therefore a longer lifetime through reduced abrasion will be realized. In most applications its not necessary to use expensive tandem designs, with two individual seals in separate seal housings. This type of seal is used for high pressure hydraulic, if in case fabric reinforced seals are not sufficient enough.

MAIN ADVANTAGES ARE

- highly abrasion resistance

- very well usable with high- and pulsating pressures

- insensible against gap extrusion

- low compression set

- suitable for hardest operating conditions

- reduced abrasion lubrication film within the joint gap between sealing lips

- in pressureless state, good density

- entrapped air within the system largely prevented

- easy to install

| APPLICATION RANGE | |

| working pressure: | ≤ 40MPa (400 bar) |

| working temperature: | - 35 °C to + 110 °C |

| sliding speed: | ≤ 0,5 m/s |

| media: | Hydraulic oil on mineral oil base |

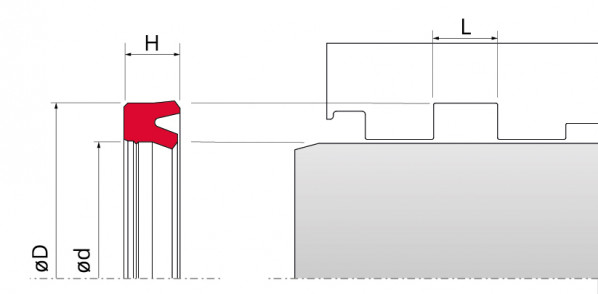

Application categories are mainly sealing of piston rods and plungers among hindered conditions with mobile- and stationary hydraulic. The dimension range orientates itself mostly by its fitting guidelines according to standards of ISO 5597/I and ISO 3320.

MATERIAL

PU008 is a wear resistant polyurethane compound with a hardness of approximately 93 Shore A. Compared to other standard Polyurethane qualities the special features of this material are: low compressions set results, high thermal stability, good characteristics against hydrolysis.

MOUNTING INSTRUCTIONS

To ensure a perfect function the BSR must have certain play in axial direction (look at measure scale). So that the sealing lips won?t be damaged, don?t pull them over sharp edges. Normally the BSR can be installed within closed grooves. In case of extremewidth of profile and diametermeasures, installing tools should be used. Normally the decrease fit for the guidelines should be laid out of H8/f7. In case of lower pressures a lager gap size on the seal back is possible.

In certain cases (high temperature, speed, specific resistance to pressure, or use of water, HFA-; HFB- fluids a.s.o.) please get in contact with our application technology.

Download | Detailed product information (PDF 367.9 kB)