| Show general overview | Load overview |

| Special dimensions on request | Request now |

GENERAL

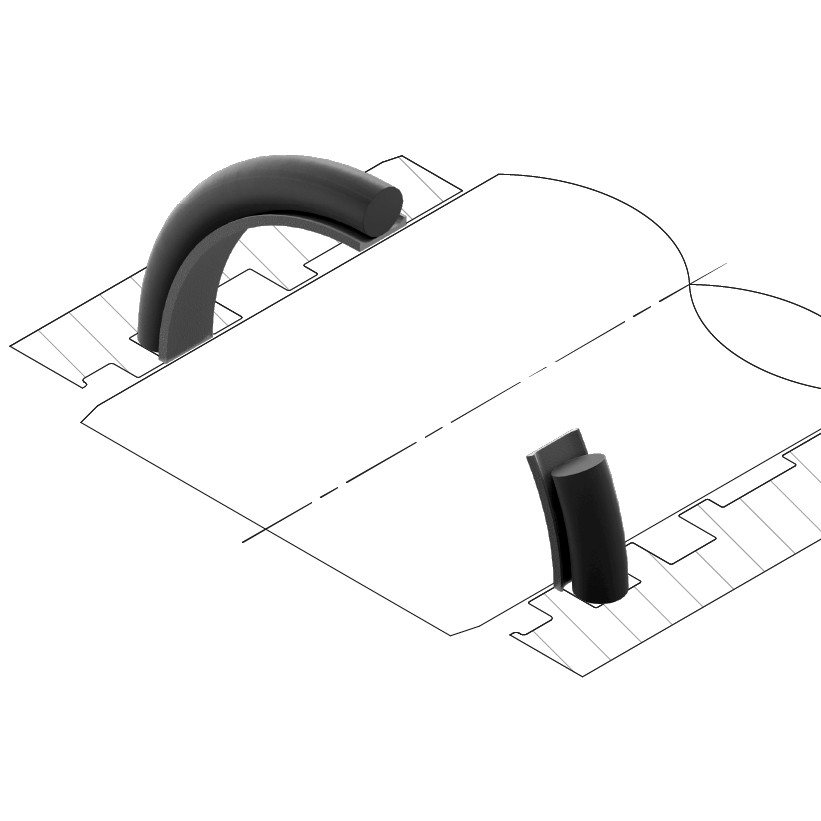

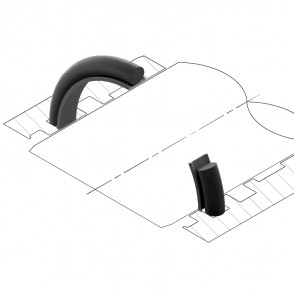

The PTFE rod seal set CRR consists off a PTFE-face seal which takes care of the dynamic sealing on the inside diameter of the rod and a clamped O-Ring which provides a pretension on the face seal and transfers the static sealing on the outside diameter. With intensified pressure of the system, the O-Ring pretension increases, caused to the design and therewith the contact pressure of the face seal against the rod. To be sealed are piston-rods and plungers within hydraulic cylinders, if compared to sealing with elastomeric seals, a lower friction is wanted.

ADVANTAGES ARE

- low sliding friction and breakaway, low stick-slip effect for consistant motion, even with low sliding speed

- highly extrusion resistant

- low abrasion

- highly temperature resistant

- multiple applications, through appropriate selection of O-Ring compound

- flexible chemical compatibility through appropriate selection of O-Ring compound

- available up to 2000 mm diameter

PLEASE NOTE

With this sealing profile it’s very important to achieve an exact guidance of the metal components through guide-tapes or wear-rings.

| APPLICATION RANGE | |

| working pressure: | ≤ 35 MPa (350 bar) |

| operation temperature: | -30 to +100 °C* >FKM 200 °C< |

| sliding Speed: | ≤ 4 m/s |

MOUNTING INSTRUCTIONS

With a diameter of <10 mm open seal housings are necessary.

INSTALLATION

For diameters < 10 mm open grooves are required.

| MATERIAL | |

| sealing rings: | modified PTFE (PT012) |

| O-rings: | NBR-elastomer with approximately 70 Shore A |

In certain cases (high temperature, speed, specificresistance to pressure, or use of water, HFA-, HFB- fluids a.s.o.), we advise to take another sealing cross section, or please contact with our application technology.

ORDER EXAMPLE

Rod diameter = 50 mm

CRR 0500 PT012 70N1 D

| CRR = | Profile |

| 0500 = | Rod Ø x 10 |

| PTO12 = | Compound |

| 70N1 = | Serial number, Last digit: O-ring code |

| D = | Cross section |

* according to compound selection of the O-Ring

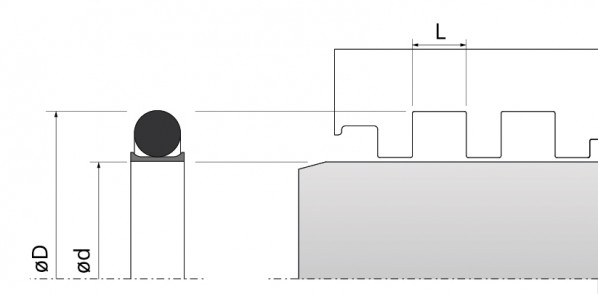

HOUSING DIMENSIONS

| Series No. | Cross-section | O-ring | Recommended rod Ø range | Groove width | Groove depth | Gap max. | Radius max. | |

| cross-section | d (mm) | |||||||

| (mm) | ≥ | < | L (mm) | G (mm) | e (mm) | R1 (mm) | ||

| Housing dimensions for O-Ring grooves without back-up ring | ||||||||

| 70N1 | A | 1,78 | 4 | 10 | 2,4 | 1,45 | 0,13 | 0,5 |

| 70N1 | B | 2,62 | 10 | 20 | 3,6 | 2,25 | 0,13 | 0,5 |

| 70N1 | C | 3,53 | 20 | 40 | 4,8 | 3,1 | 0,15 | 0,5 |

| 70N1 | D | 5,33 | 40 | 120 | 7,1 | 4,7 | 0,17 | 0,9 |

| 70N1 | E | 6,99 | 120 | 400 | 9,5 | 6,1 | 0,25 | 0,9 |

| Housing dimensions for O-Ring grooves with 1 back-up ring | ||||||||

| 71N1 | A | 1,78 | 4 | 10 | 3,8 | 1,45 | 0,13 | 0,5 |

| 71N1 | B | 2,62 | 10 | 20 | 5,0 | 2,25 | 0,13 | 0,5 |

| 71N1 | C | 3,53 | 20 | 40 | 6,2 | 3,1 | 0,15 | 0,5 |

| 71N1 | D | 5,33 | 40 | 120 | 8,8 | 4,7 | 0,17 | 0,9 |

| 71N1 | E | 6,99 | 120 | 400 | 10,5 | 6,1 | 0,25 | 0,9 |

| Housing dimensions for O-Ring grooves with 2 back-up rings | ||||||||

| 72N1 | A | 1,78 | 4 | 10 | 3,8 | 1,45 | 0,13 | 0,5 |

| 72N1 | B | 2,62 | 10 | 20 | 5,0 | 2,25 | 0,13 | 0,5 |

| 72N1 | C | 3,53 | 20 | 40 | 6,2 | 3,1 | 0,15 | 0,5 |

| 72N1 | D | 5,33 | 40 | 120 | 8,8 | 4,7 | 0,17 | 0,9 |

| 72N1 | E | 6,99 | 120 | 400 | 10,5 | 6,1 | 0,25 | 0,9 |

Special sizes are available quickly.

O-RING DESIGNATIONS IN PTFE-SEALS

| Material | Härte | OR-Code |

| NBR | 70+/-5 | N1 |

| FKM | 75+/-5 | V2 |

| NB 304 (HNBR) | 75+/-5 | N3 |

| EPDM | 75+/-5 | E4 |

| NB 578 | 75+/-5 | N5 |

| NBR | 90+/-5 | N6 |

| Silikon | 70+/-5 | S7 |

| HNBR | 80+/-5 | N8 |

| FFKM | 80+/-5 | V9 |

Download | Detailed product information (PDF 394.0 kB)