| Show general overview | Load overview |

| Special dimensions on request | Request now |

E5R

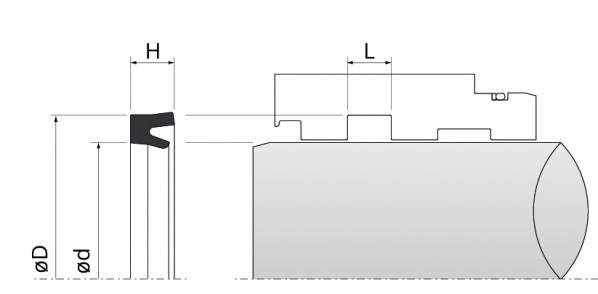

The lip-ring profile E5R was especially developed for application with pneumatic. The series of the standard line (type series), profile E5R, is equivalent to the rod diameters, according to ISO 3320, as well as CETOP RP 51 P. The standard alignment is exchangeable with the previously used profile C1R, in pneumatics. The dimension of the lip of the profile E5R was optimised for application with pneumatics.

ADVANTAGES ARE

- deployable with maintained, as well as oil-free compressed air, through special seal geometry

- after accurate initial lubrication, favourable friction conditions, through lubrication film retentive lip design

- high life time, through usage of well proven elastomers

- robust version, through ideal sealcross-section

- high reliability, through a tight-hold within the ground of the groove

- easy snap mounting within closed grooves, through kidney shaped deformation

- long time of operation (service time), through usage of well proven elastomers

| APPLICATION RANGE | |

| working pressure: | ≤ 1,6 MPa (16 bar) |

| working temperature: | - 30 °C bis + 80 °C, NBR > FKM to + 200 °C < |

| - 35 °C up to + 80 °C, PU | |

| sliding speed: | ≤ 1 m/s |

| media: | Maintained, as well as dry and oil-free, compressed air (after initial lubrication) |

MATERIAL

Is a proven and tested standart-elastomer on NBR basis, with a hardness of approximately 78 Shore A. FKM compounds for high temperature and other mixtures for application with low temperatures, are possible. Available measurements in Polyurethane (PU) are listed separately.

MOUNTING INSTRUCTIONS

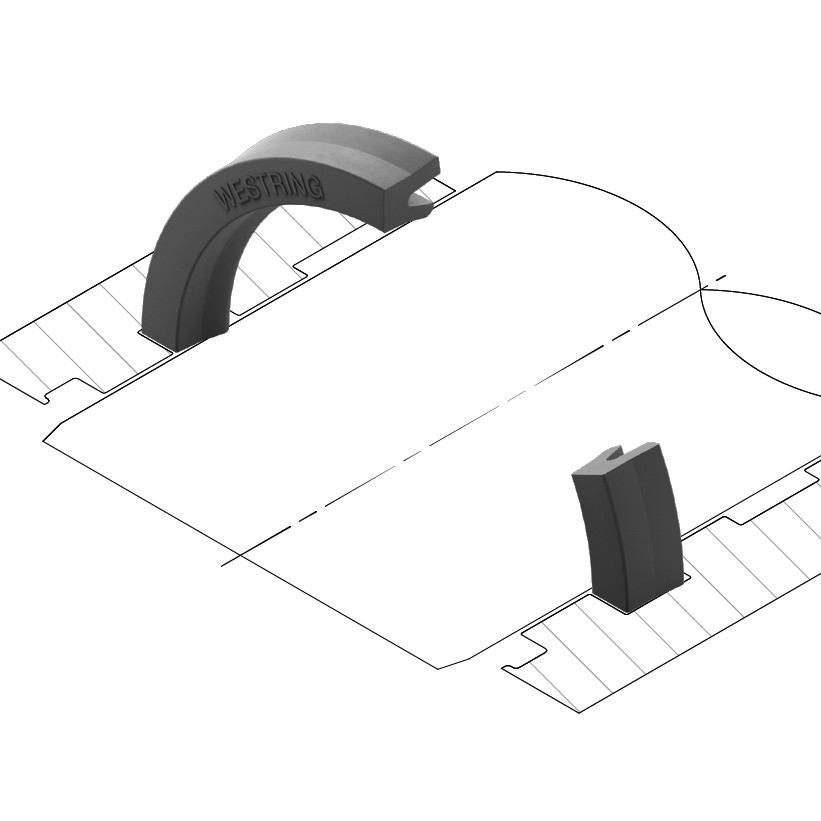

To ensure a perfect function, the E5R must have a certain play in axial direction (look at measure scale). So that the sealing lips won´t be damaged, don´t pull them over sharp edges. Through kidney shaped deformation, the seal is easily snapped into closed grooves.

The dynamic seal-lip gets his final measurement after application within the groove. To achieve a good durability, apply a closed lubrication film upon the piston rod. So this lubrication film wont be damaged by a wiper, we recommend using, for operation in oil-free air, a wiper profile A2R, which was developed for pneumatics.

Note: Depending on the seal cross-section diameter, a divisible installation space with nominal diameter ≤ Ø 25 mm is advisable.

In certain cases (high temperature, speed, specific resistance to pressure, or use ofwater, HFA-, HFB- fluids a.s.o.) please contactwith our application technology.

Download | Detailed product information (PDF 368.0 kB)