| Show general overview | Load overview |

| Special dimensions on request | Request now |

ELR

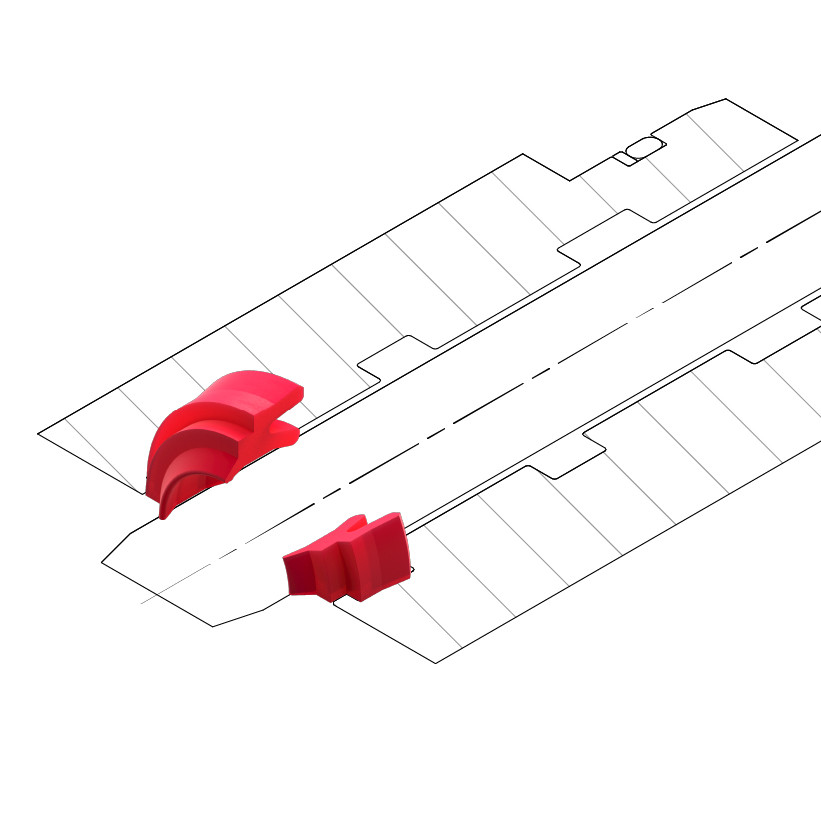

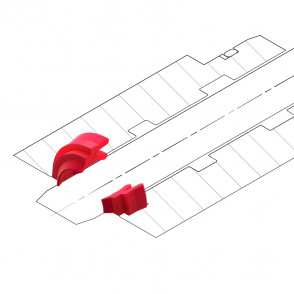

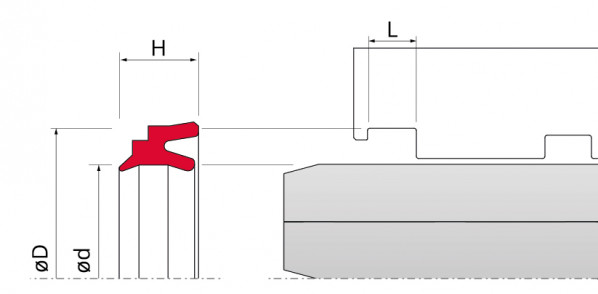

The pneumatics seal wiper element profile ELR combines two functions in one seal: Sealing and wiping of piston rods at small pneumati cylinders and valve tappets.

ADVANTAGES ARE

- sealing and wiping in one element

- small place requirement but full function

- ideal housing finish

- low mounting effort

- adapted sizes to CETOP fitting dimensions.

- simple and economical fitting area

- no additional axial safeguard required

- due to special lip geometry, even usable with dry and oil-free air after initial lubrication

- smooth running thanks to optimal tuning of the dynamicwiper and seal lips

- no corrosion danger because of the purely polymer part

| APPLICATION RANGE | |

| working pressure: | standard compound ≤ 1,0 MPa (10bar), |

| NBR ≤ 1,6 MPa (16bar), HPU | |

| working temperature | - 10 °C to + 80 °C, NBR > + 200 °C FKM < |

| - 35 °C to + 80 °C, HPU | |

| surface speed: | ≤ 1 m/s |

| media: | lubricated as well as dry and oil-free air (after initial lubrication) |

MATERIAL

NBR-based special elastomer SFR© with a hardness of approx. 85 Shore A. This mixture features especially well running properties. Design and deliverable dimensions for HPU, see seperated table. For high or low temperature applications, FKM-mixtures and further special compounds are available.

MOUNTING INSTRUCTIONS

The seal / wiper elemnt ELR is easy to be snapped into its fitting area when the piston rod is demounted. No further axial safeguard is necessary thanks to the outline of the profile. To avoid damage to the wiper and sealing lips, those should not be drawn over sharp edges during installation. An initial lubrication of the mating surfaces on assembly is important for very long service life.

For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

Download | Detailed product information (PDF 334.4 kB)