| Show general overview | Load overview |

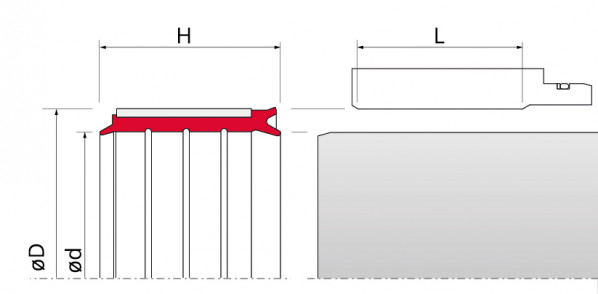

| Special dimensions on request | Request now |

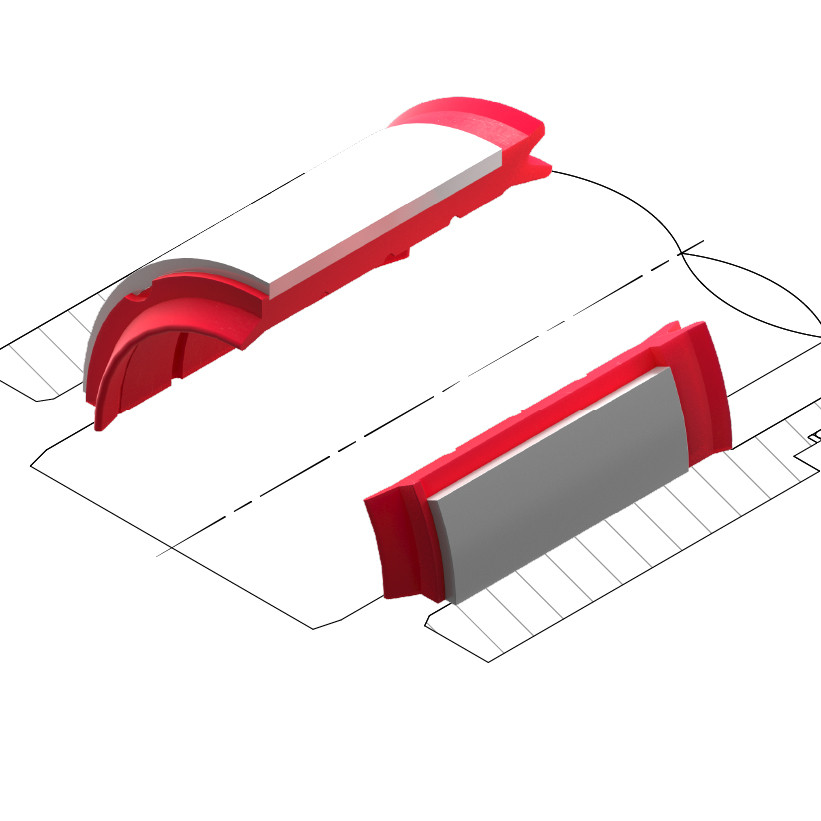

EPR

The combination element profile EPR is designed for use in the pneumatics. It completes three tasks in one profile: Wiping, sealing and guiding of piston rods. It is mounted by pressing-in of the aluminium sleeve at the outside diameter into a bored groove, that ensures a close fit.

ADVANTAGES ARE

- simple mounting by means of easy-to-make mounting sleeves

- economical to manufacture straight fitting area

- low storage costs, instead of three units with conventional constructions

- low friction coefficients and long working life is reached with the optimized geometry of the sealing and wiping lip. The guide part is equipped with grooves which simplifies the initial lubrication

- usable with dry and oil-free air after initial lubrication

| APPLICATION RANGE | |

| working pressure: | ≤ 1,6 MPa (16 bar) |

| working temperature: | – 35 °C to + 80 °C |

| surface speed: | ≤ 1 m/s |

| Media: | maintained as well as dry and oil-free air (after initial lubrication). |

MATERIAL

The combination element EPR consists of highly wear-resistant polyurethane at the wiper and seal lips as well as at the guide surface. The press-in sleeve resp. the supporting part is made of an aluminium alloy, that is chemically bonded to the polyurethane compound. The supporting parts are available from other materials. Please ask if needed.

MOUNTING INSTRUCTIONS

The combination element EPR is pressed into the bore with the aluminium outside body. Hereby, a close fit in the cylinder housing is given, that serves for the fixation of the combination element. To avoid damage to the wiper and sealing lip, those should not be drawn over sharp edges during installation. While pressing the mounting sleeve into the bore, pressure should only be put on the aluminium body of the combination element.

For special requirements (temperature, speed etc.), please contact our Consultancy Service, so that suitable materials and/or designs can be recommended.

Download | Detailed product information (PDF 358.8 kB)