| Show general overview | Load overview |

| Special dimensions on request | Request now |

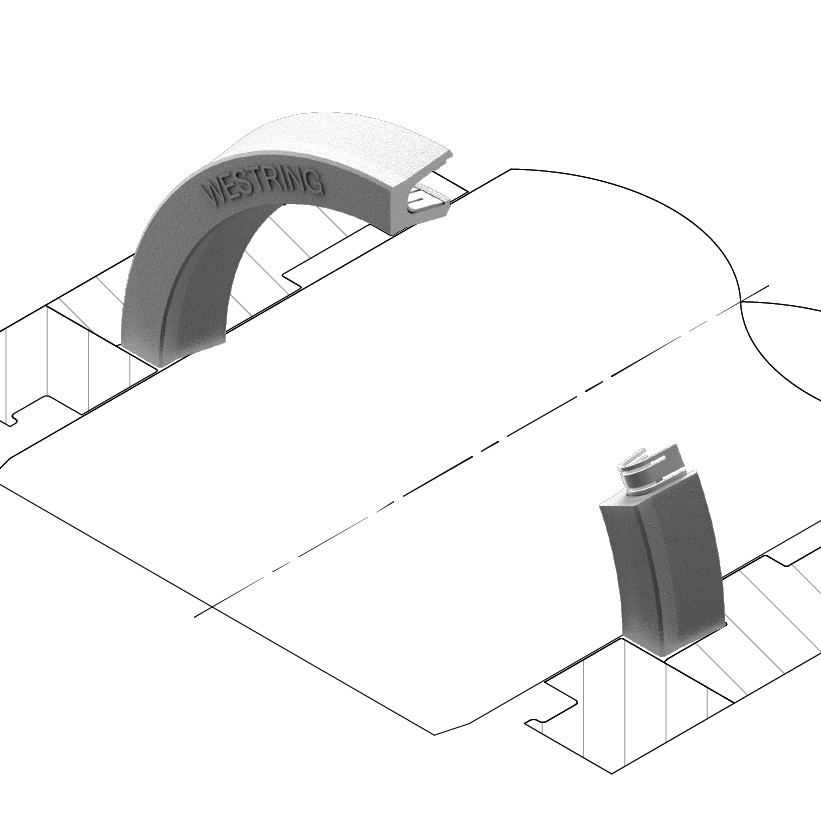

JSR

The JSR profile is a single acting rod seal. It consists of an U-shaped PTFE jacket and a V-shaped corrosion resistant spring. This makes the seal permanently elastic, independent of operating temperature changes, pressure, etc. The pre-stressing of the PTFE ring and the mechanic pretension power of the spring creates the static seal effect. The consequent pressing force gets strengthened by the system pressure, so that the total seal pressing grows by increasing working pressure. The JSR sealing can be used in O-ring fitting areas according to DIN 3771, MIL-G-5514F and ARP568.

ADVANTAGES ARE

- resistant to most fluids and chemicals

- high seal pressing

- high and prolonged recovery

- low coefficient of friction

- good dry operation attributes

- broadly based application scope by a tall variety of materials

- excellent resistance to ageing

- unlimited shelf life

| APPLICATION RANGE | |

| working pressure: | 35 Mpa (350 bar) |

| working temperature: | - 150 °C up to + 225 °C |

| surface speed: | 15 m/s |

A large application scope is given by the variety of combinations of the sealing and spring materials (for example the possible sterilization). It can be applied in apparatus engineering and plant constructions, pharmaceutical processings, cryogenics, food and beverage processings, nuclear energy technologies, aeronautics, vacuum processings as well as natural gas and mineral oil machineries.

| MATERIAL | |

| joint washer: | PT031 (modified PTFE + 15 % carbon) |

| spring: | Stainless steel 1.4301 (AISI 301) |

ORDER EXAMPLE

JSR 0500 PT031 2130 D

| Rod diameter: | 50 mm |

| JSR = | Profile |

| 0500 = | Rod Ø x 10 |

| PT031 = | Compound |

| 2130 = | Serial number, Last digit: spring code |

| D = | Cross section |

MOUNTING INSTRUCTIONS

For special applications it is recommendable to use a sealing cross section, reduced or stepped up, that differs from standard, In these cases replace the standard cross section code (e.g. „D“) by the desired one (e.g. „B“ or „C“). Generally a splitted housing is to prefer. This data represents the maximum limit of strength and is closely interrelated. Under difficult conditions it is not advisable to make use of all values simultancously at maximum limit. For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy service.

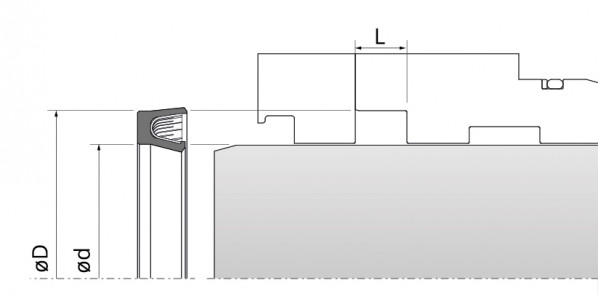

HOUSING DIMENSIONS

| Series No. | Cross-section | O-ring | Recommended inner Ø range | Groove width | Groove depth | Gap max. | Radius max. | |

| cross-section | d (mm) | |||||||

| (mm) | ≥ | < | L (mm) | G (mm) | e (mm) | R1 (mm) | ||

| Housing dimensions for O-Ring grooves without back-up ring | ||||||||

| 2100 | A | 1,78 | 4 | 10 | 2,4 | 1,45 | 0,13 | 0,4 |

| 2110 | B | 2,62 | 10 | 20 | 3,6 | 2,25 | 0,13 | 0,4 |

| 2120 | C | 3,53 | 20 | 40 | 4,8 | 3,1 | 0,15 | 0,6 |

| 2130 | D | 5,33 | 40 | 120 | 7,1 | 4,7 | 0,17 | 0,8 |

| 2140 | E | 6,99 | 120 | 700 | 9,5 | 6,1 | 0,25 | 0,8 |

| Housing dimensions for O-Ring grooves with 1 back-up ring | ||||||||

| 2300 | A | 1,78 | 4 | 10 | 2,4 | 1,45 | 0,13 | 0,4 |

| 2310 | B | 2,62 | 10 | 20 | 3,6 | 2,25 | 0,13 | 0,4 |

| 2320 | C | 3,53 | 20 | 40 | 4,8 | 3,1 | 0,15 | 0,6 |

| 2330 | D | 5,33 | 40 | 120 | 7,1 | 4,7 | 0,17 | 0,8 |

| 2340 | E | 6,99 | 120 | 700 | 9,5 | 6,1 | 0,25 | 0,8 |

Special sizes are available quickly.

DIN material no 1.4310.

| Code | 0 = stainless steel (standard) |

| 2 = for aggressive media | |

| 3 = seal to be finished with silicone filing, stainless steel spring, for example for food industry or medical applications | |

| 4 = seal to be finished with silicone filling and spring for very aggressive media | |

| 5 = stainless steel Helico spring |

Download | Detailed product information (PDF 373.2 kB)