| Show general overview | Load overview |

| Special dimensions on request | Request now |

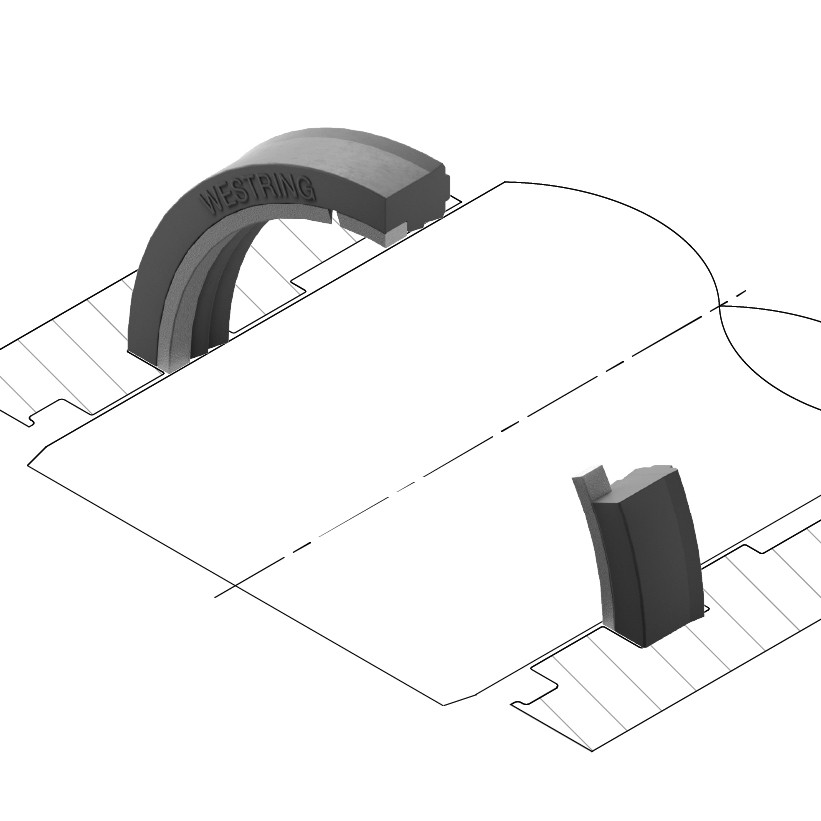

R3R

The rod seal profile R3R is a combination of an elastomer seal element and a specific PTFE back-up ring to avoid the extrusion. By this structure a excellent density and also the smoothly run of the seal is warranted. Especially in the low-pressure area this wear-resistant seal profile works nearly leakage-free.

ADVANTAGES ARE

- Impervious to long downtimes

- High seal effect even in zeropressure condition

- Materials do not tend to the absorption of water (hydrolysis), often with PU materials

| APPLICATION RANGE | |

| working pressure: | ≤ 31,5 MPa (315 bar) |

| working temperature: | - 30 °C to + 110 °C > FKM to + 200 °C < |

| surface speed: | ≤ 0,5 m/s |

Applications in sealings at piston rods, at easy and middle hydraulics with often changes of pressure and movement.

| MATERIAL | |

| Seal element: | NBR- or FKM-based elastomer |

| Back-up ring: | PTFE Compound |

MOUNTING INSTRUCTIONS

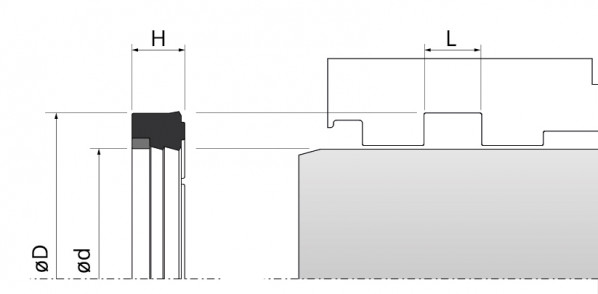

To guarantee a faultless function, the R3R has to have free play in the axial direction (see table). To avoid damage to the sealing lip, the seals should not be drawn over sharp edges during installation. In normal case the R3R is mountable on closed grooves. Assembly aids are to be used at extreme widths of section or proportions of the diameters. Normally the fit should be laid out on H8/f7. A larger gap size at the back of the seal is possible at lower pressures.

For special cases of application (high temperatures, speed, specific pressure, use inwater, HFA-, HFB-fluids etc.) please get in contactwith our consultancy service.

Download | Detailed product information (PDF 371.3 kB)