or

| Show general overview | Load overview |

| Special dimensions on request | Request now |

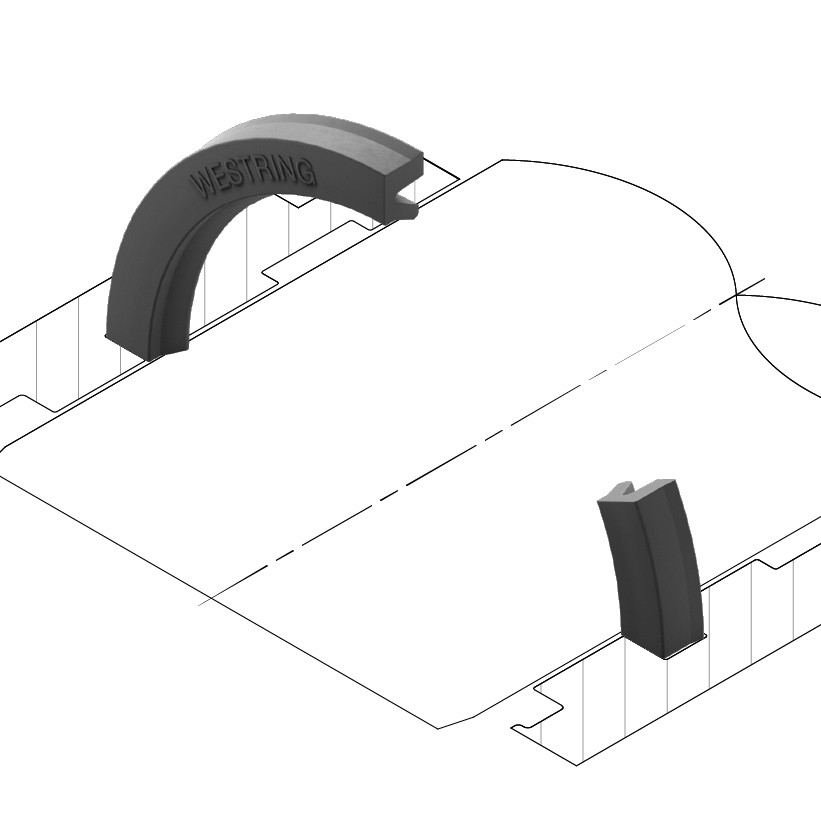

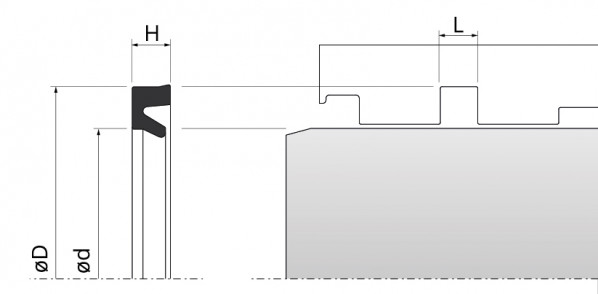

The profile Z9R is a lip seal which is, with regard to its lip geometry and cross section, especially designed for the use in the pneumatics.

ADVANTAGES ARE

ADVANTAGES ARE

- smooth running due to small seal height

- space-saving fitting areas

- low static friction (due to a small cross section, thus low dynamic friction)

- improved running characteristics due to the optimization of the lip geometry and the use of the established SFR-compounds

- lip ring design provides high functional reliability

- qualified for cylinders with stop position damping

- long service life after thorough initial lubrication

- even usable in dry or oil-free compressed air

- very simple snap mounting in the seal grooves

APPLICATION RANGE

| operating pressure: | ≤ 1,6 MPa (16 bar) |

| operating temperature: | - 20 °C up to + 80 °C >FKM to 200 °C< |

| surface speed: | ≤ 1,0 m/s (pneumatics) |

| media: | lubricated as well as dry and oil-free pressure air after initial lubrication |

The profile Z9R is especially well-suited as rod seal in demanded compact pneumatic cylinders.

MATERIAL

The compound is the proven and well-tried, NBR-based special elastomer with a hardness of approx. 80 Shore A. Biggest advantages is the good running characteristic in the range of semi-fluid friction. Furthermore compoud varieties on the basis of EPDM or FKM are possible.

MOUNTING INSTRUCTIONS

The profile Z9R is to snap easily into grooves from 25 mm nominal diameter by kidney-shaped deformation. Open groove designs have to be preferred for seals with smaller nominal diameter. To avoid damage to the seal lips, they should not be drawn over sharp edges during installation. So, the edges in the fitting area should be rounded. Due to the oversize at the outside diameter, the seal has a close fit in the groove and the specified size of the seal lip is only achieved after the installation. Before mounting, a closed lubricating film should be spread out on the rod. Hence, the dry operation and a long service life are ensured. The design of the wiper has to be special to not destroy the lubricating film during use. Therefore we recommend our profile A2R with rounded wiper lip.

For special cases of application (high temperatures, speed, specific pressure, use in water, HFA-, HFB-fluids etc.) please get in contact with our consultancy

service.

Download | Detailed product information (PDF 391.9 kB)