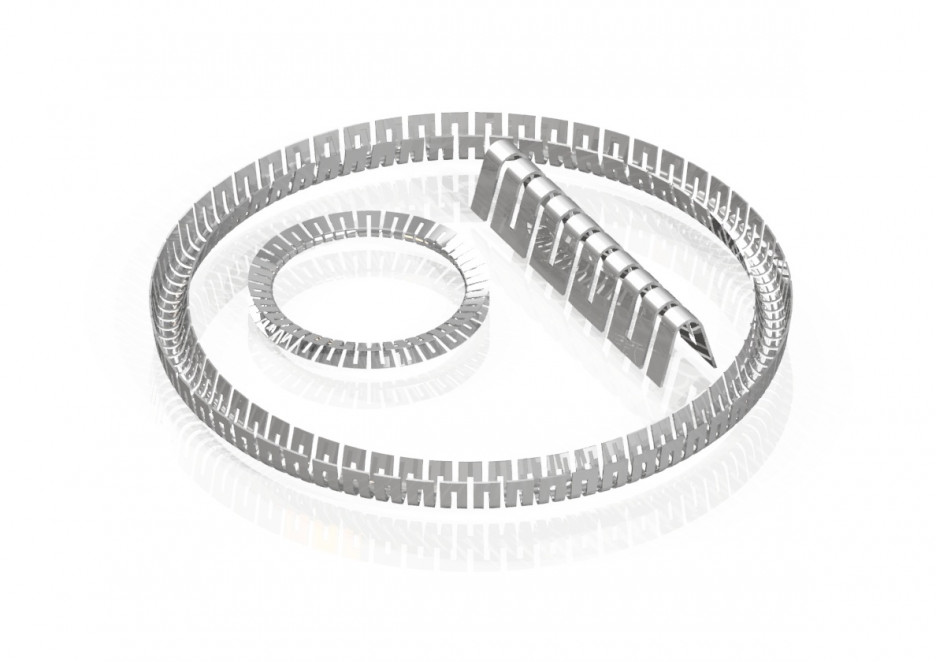

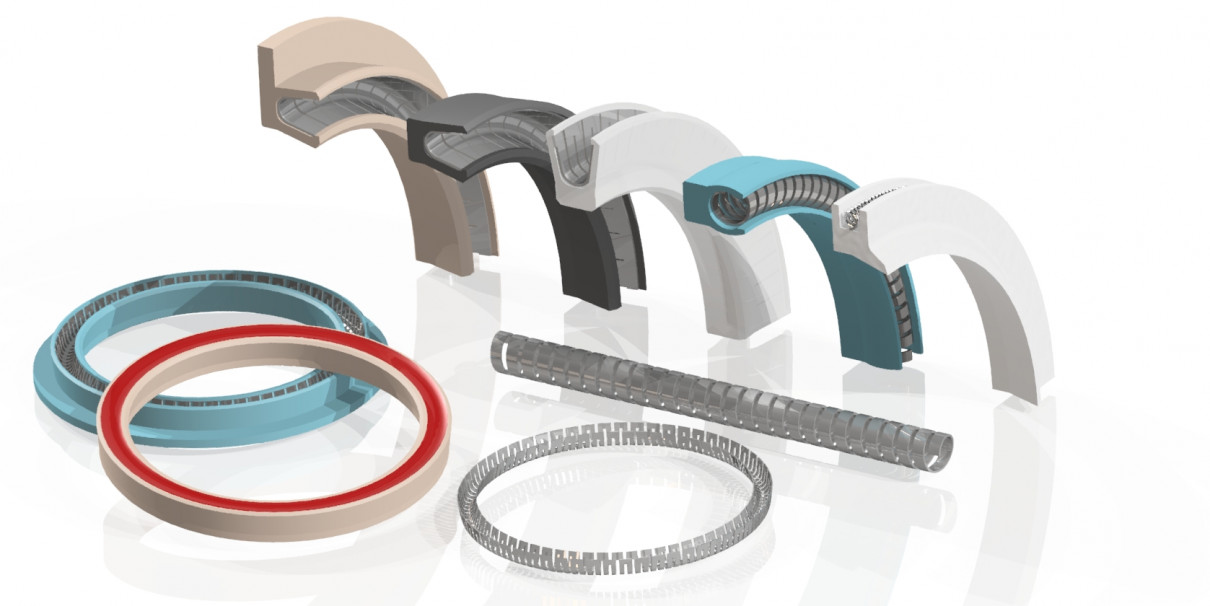

Spring-assisted seals are made of highly resistant materials (e.g. PTFE) that are pre-tensioned by a metal spring incorporated inside. The spring ensures a constant contact pressure and provides a durable, efficient seal - regardless of temperature, chemicals or pressure conditions.

Application - For demanding applications

Our spring-loaded seals are used in the chemical and pharmaceutical industries:

- Chemical and pharmaceutical industries: Sealing aggressive media and processes with high temperatures and pressures.

- Mechanical engineering: Sealing pistons and rods in hydraulic and pneumatic systems.

- Food technology: Use in FDA-compliant and biocompatible systems.

- Aerospace: Applications with vacuum and large temperature fluctuations.

- Hydrogen technology: Safe solution for tanks and pipes in H2 environments.